CO2 and METHANOL

A QUESTION OF BALANCE

Reducing global Greenhouse Gases emissions to net zero by 2050 increasingly hangs on our ability to make a significant change in our relationship with CO₂. Perhaps the most critical component of the global economy, until now, we have treated it as a waste stream and discarded it in the atmosphere. For the world to end its reliance on fossil fuels, CO₂ must instead be treated as a precious resource that we re-cycle and reuse. Carbon will continue to be needed to support human progress, but we must manage it within a closed loop system to make it sustainable.

Since 2006 CRI has pioneered the development of the technology required to produce sustainable methanol from carbon emissions and is rolling it out to help partners achieve industrial scale Carbon Capture Utilisation and Storage (CCUS) projects.

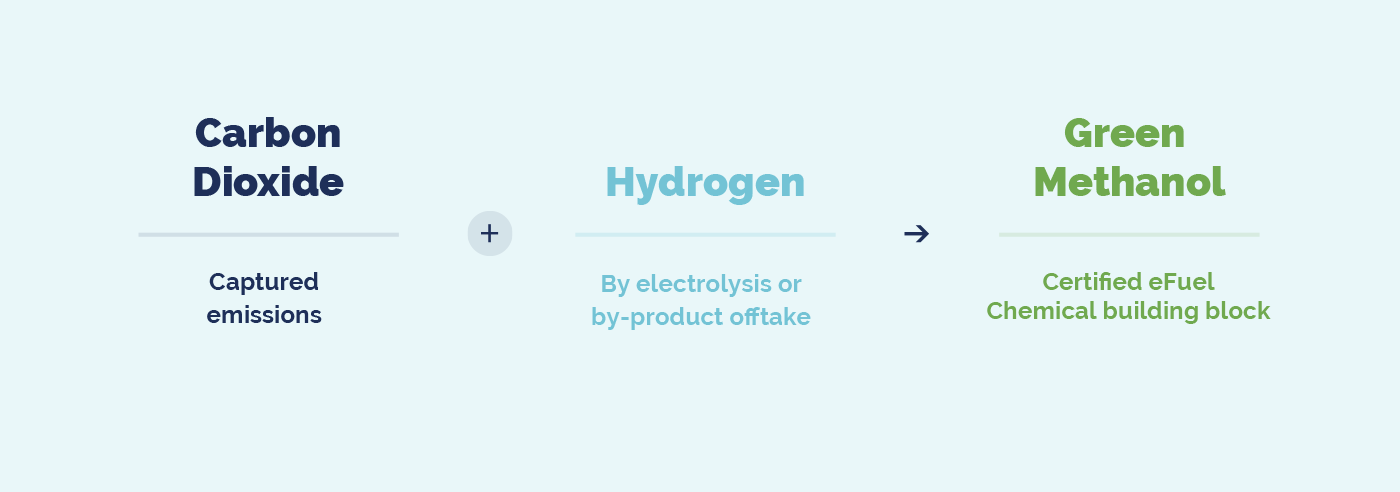

Capturing CO₂ emissions, combining them with green or recovered H₂ to produce methanol and feeding them back into our industrial processes as a renewable energy source and feed stock, provides an accelerated path toward a Circular Economy.

Renewable methanol enables a rapidly growing proportion of the global economy to become carbon neutral using existing processes and infrastructures, by enabling collaboration between different sectors to reduce overall CO₂ emissions.

In China, a CO₂-producing industry is supplying carbon neutral methanol as raw material for chemical production, instead of emitting.

In Scandinavia a CO₂-producing smelter will soon supply clean burning fuel for maritime transport.

THE CARBON DIOXIDE CHALLENGE

Compared with the pre-industrial era, levels of CO₂ in our atmosphere are now 50% higher and still rising. The first 25% of that increase took 200 years, but it has taken only 30 years to double. The primary cause of that increase is our dependence on fossil fuels as an energy source.

The consequence of this sharp rise is going to be global warming and the current levels of CO₂ already represent an unavoidable temperature rise, accompanied by environmental effects such as rising sea levels.

Our commitment now, as a global community, is to limit that temperature rise to 1.5 °C ideally and 2.0 °C maximum.

Reducing CO₂ emissions will require a transition away from fossil energy sources and a significant increase in renewable energy generation and CCUS.

THE JOURNEY TO CLIMATE NEUTRALITY

While switching to wholly renewable energy sources and large-scale carbon capture and storage are the headline ambitions, there are wide gaps to bridge in terms of technology, economy, policy and behaviour.

A practical transition is required, delivering ever-increasing reductions in GHG emissions within existing industrial processes and value chains. By implementing a Circular Economy approach to as many sectors as possible, the journey to carbon neutrality can be made through practical steps, not reliant on disruptive hypothetical leaps.

Renewable methanol produced from captured offgas CO₂ and non-fossil hydrogen can replace fossil hydrocarbons in a huge swathe of industrial and domestic sectors, bring them ever-closer to carbon neutrality. The global market for methanol as a fossil substitute is predicted to be 500mt by 2050.

METHANOL APPLICATIONS

The applications for methanol are already widespread due to its desirable properties. It can be transported and stored easily and safely, being a liquid at room temperature. It is biodegradable and a highly efficient energy carrier, burning cleanly and producing no soot or particulates.

Methanol is commonly used as a chemical feed stock for the production of plastics, glue, building materials, paints and solvents and is the most commonly used carbon source for removing contaminants from wastewater.

It has a high octane rating (109 RON) providing better energy conversion than either gasoline or diesel. In many regions different blends of methanol with gasoline diesel are in use, with 3% and 15% already seen in Europe and China respectively. Authorities in China are also promoting M100 (100% methanol) in light vehicles, buses and trucks. Marine transport is increasingly turning to methanol as a clean replacement for bunker fuel and it continues to grow in popularity for industrial boilers and cookstoves.

-

CHEMICALS

-

GASOLINE BLENDING

-

BIODIESEL

-

WASTEWATER TREATMENT

METHANOL -

COMMERCIALLY VIABLE, WHOLLY RENEWABLE

CRI has pioneered the CO2 to methanol conversion technology required to produce both renewable e-methanol and recycled carbon methanol. The first renewable e-methanol plant started producing in 2012 and further pilot plants have been completed. In 2020 the first plant to use blast furnace offgas was commissioned, and the first commercial scale plant came on stream in 2022, with a capacity of 110,000 tons of recycled carbon methanol per year.

From 2012 until 2020, CRI pioneered the use of eFuels through the sale of renewable methanol – Vulcanol™ – commercially for various applications to clients in Europe and China. Over the whole product lifecycle, from extraction and production through to end use, Vulcanol™ has achieved carbon emission reductions of more than 90% compared with fossil methanol.

CRI has developed world beating expertise in each stage of the value chain. Our Emissions to Liquid™ (ETL) technology solves the problems of conversion efficiency, renewable energy availability, fluctuations and scalability. It is technically mature, economically competitive and being implemented at industrial scale.

CREATING METHANOL SUSTAINABLY

CRI’s ETL process technology requires a source of CO₂ and H₂. Where both are captured from waste streams from industry, the product is called recycled carbon methanol. With access to a source of renewable electricity, electrolysis is used to produce H2 from water, resulting in ‘renewable e-methanol’.

Converting power to renewable e-methanol – storing power as a liquid – provides advantages over other Power-to-X approaches, being simpler and more flexible. In terms of scale and time, methanol enables an energy storage capability orders of magnitude greater than most other methods. The stranded energy from an entire season can be converted into stable, safe and easily stored liquid and later transported across the globe to where it is needed.

It is easier and safer to store and transport than hydrogen, and actually contains a higher density of hydrogen than the equivalent liquid volume of pure H₂. It has diverse fuel applications and a large demand as an existing feed stock for the chemical industry.

Renewable methanol is able to technically, economically and practically reduce the greenhouse gas emissions of significant sections of the global economy.

CRI ARE WORLD LEADERS IN CO₂ TO METHANOL TECHNOLOGY.